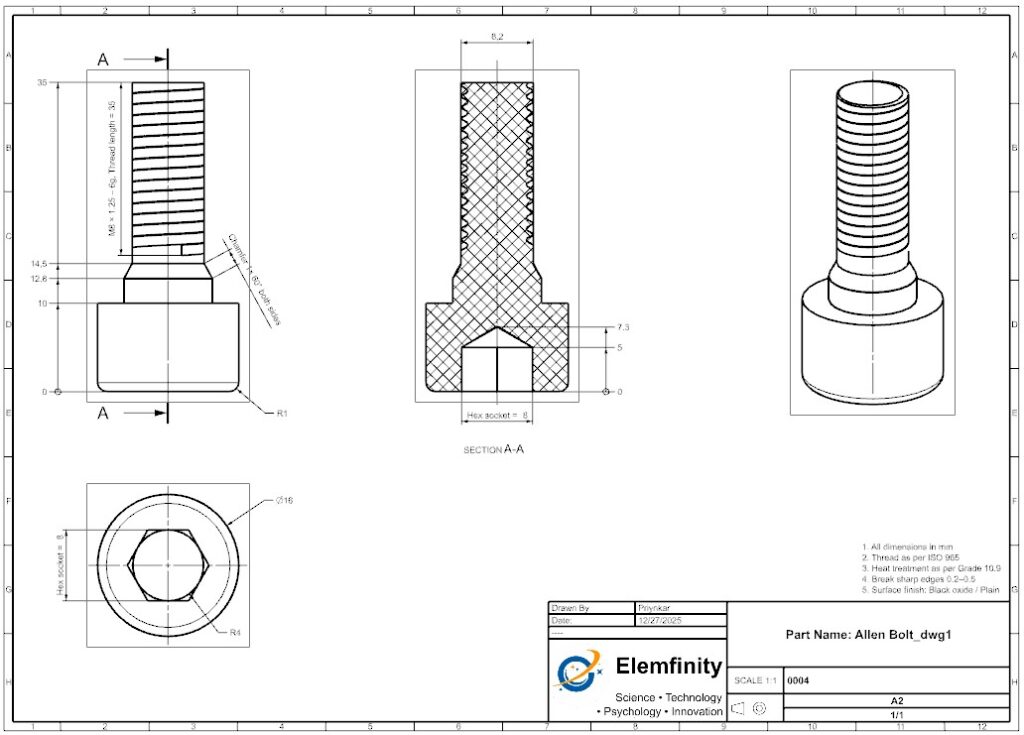

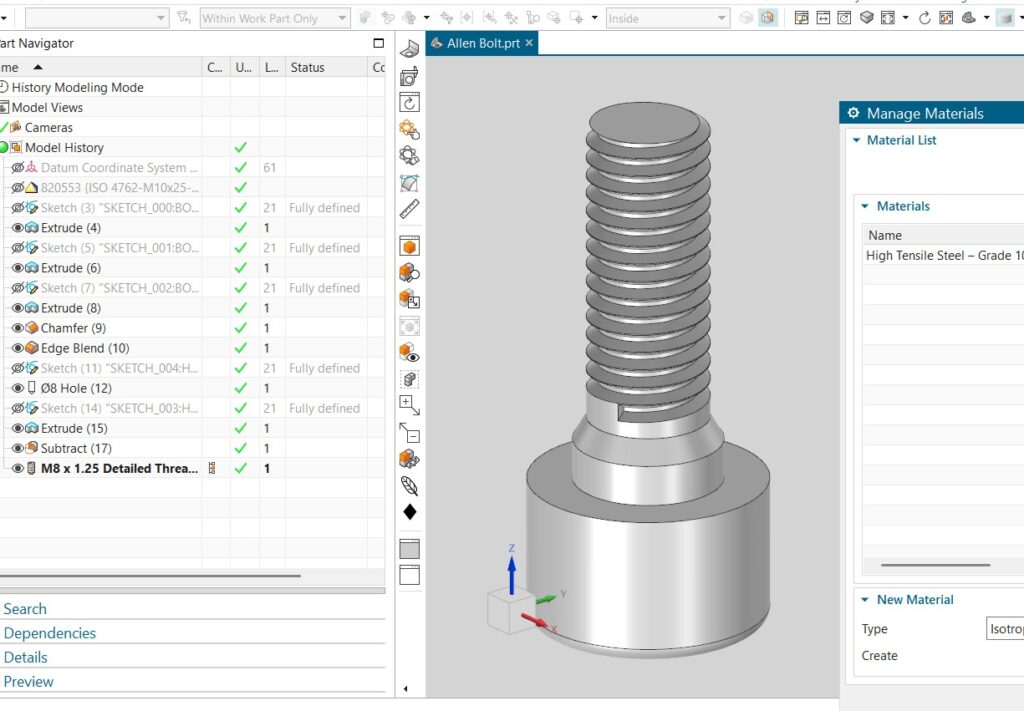

An Allen bolt, also known as a socket head or Allen head bolt, is a fastener with a hexagonal recess in its head, allowing it to be tightened or loosened using an Allen key or hex wrench. This design provides high torque capability and reliable clamping force, making Allen bolts ideal for applications where strength, precision, and accessibility are critical, such as in trucks and trailers.

Applications in Trucks and Trailers

Allen bolts are commonly used to secure critical components in heavy vehicles, including engine assemblies, chassis joints, suspension systems, and various machinery parts. Their compact head profile allows installation in confined spaces, which is especially useful in the tight engine bays and structural assemblies found in trucks and trailers. They are also valued for their resistance to vibration loosening, ensuring the safety and durability of vehicle connections under heavy loads and harsh operating conditions.

Types and Materials

- Allen bolts are available in several head styles, such as socket head cap, button head, and flat head, each suited to different assembly needs.

- Common materials include alloy steel and stainless steel, providing high tensile strength and corrosion resistance for demanding environments like those encountered in truck and trailer operations.

- Sizes range from small (M2) to large (M30), with selection based on the specific load and application requirements.

Advantages

- High torque and strength for secure fastening in critical assemblies.

- Compact design enables installation in restricted spaces.

- Resistant to stripping and loosening, enhancing vehicle safety and reliability.

- Corrosion-resistant options extend service life in outdoor and harsh environments.

Allen bolts are essential in truck and trailer manufacturing and maintenance, offering a reliable solution for securing vital vehicle components where durability and accessibility are paramount.