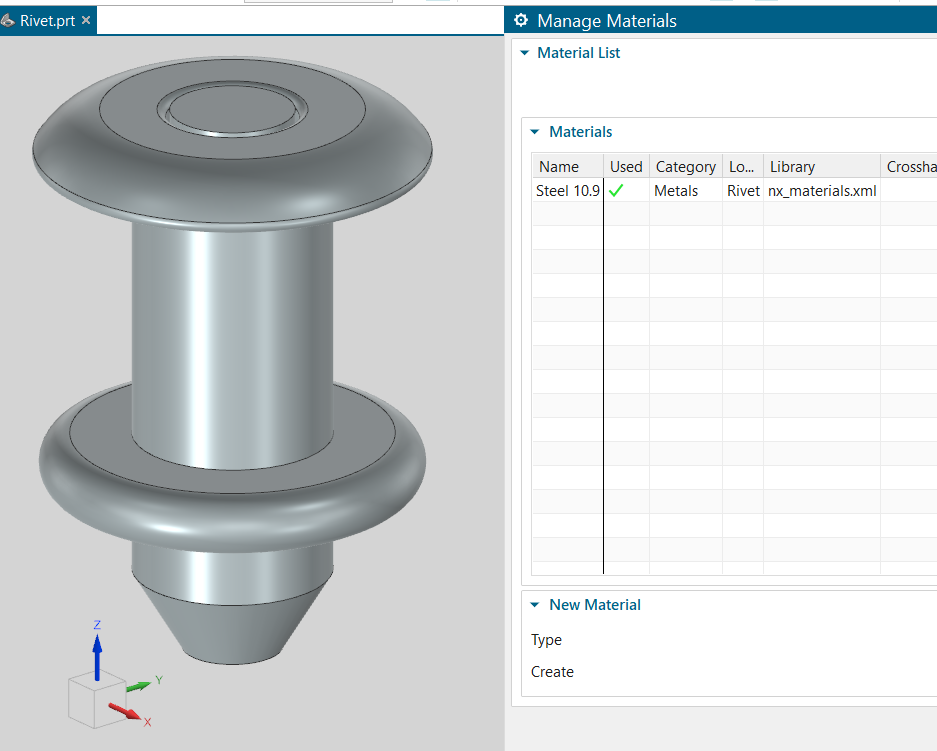

A rivet is a permanent mechanical fastener used to join two or more sheets or components, commonly in truck, trailer, automotive, aircraft, and structural applications. Rivets are trusted for their ability to create strong, vibration-resistant joints, which is especially valuable for vehicles exposed to dynamic loads and harsh road conditions.

Types of Rivets

- Solid Rivets: Traditional and strong, used for heavy-duty joints in chassis and frame assemblies.

- Blind (Pop) Rivets: Allow installation from a single side; popular for truck and trailer body panels, exhaust systems, and interior assemblies where access is limited.

- Structural Blind Rivets: Provide enhanced strength for critical connections in trailer subframes and other high-stress regions.

- Semi-Tubular Rivets: Easier to install than solid rivets due to a partially hollow shaft; used where moderate strength is sufficient, commonly in brake lining and lightweight assemblies.

- Drive Rivets: Frequently used in sheet metal fabrication and situations requiring fast and simple installation without special tools.

- Self-Piercing Rivets: Fasten sheets without pre-drilling, improving speed and waterproofing for automotive bodywork.

Applications in Trucks and Trailers

- Body Assembly: Blind rivets and structural blind rivets are widely used for fastening panels, doors, and trim on truck and trailer bodies due to their reliability and ease of one-sided access.

- Exhaust and Pipe Systems: Blind rivets secure components where welding is impractical and access is limited.

- Interior and Cab: Specialty rivets fasten dashboards and interior features, offering secure and neat finishes.

- Brake Linings: Semi-tubular rivets join brake linings to shoes, balancing installation ease and mechanical strength.

Performance and Materials

- Rivets for trucks and trailers are typically made from aluminum, steel, or stainless steel for high strength, corrosion resistance, and longevity in outdoor environments.

- Design features like wide flaring heads and locking mechanisms increase the resistance to pull-out and vibration loosening, crucial for safe vehicle operation.

- The choice of rivet depends heavily on load, accessibility, required strength, and assembly speed, allowing manufacturers to balance cost, performance, and serviceability.

In summary, rivets play a pivotal role in heavy vehicle manufacturing and repair by ensuring permanent, reliable, and vibration-proof joining of multiple vehicle components, with specific types tailored to diverse truck and trailer requirements.