K-factor has different meanings depending on the context:

1. Viral Growth (Marketing & Apps):

- K-factor is a metric for measuring viral growth, indicating how many new users each existing user brings in through referrals or sharing.

- Calculated with:

where= average number of invites per user, and

= conversion rate of those invites.

- K-factor > 1 means rapid growth, K-factor = 1 signals steady state, and K-factor < 1 suggests decline.

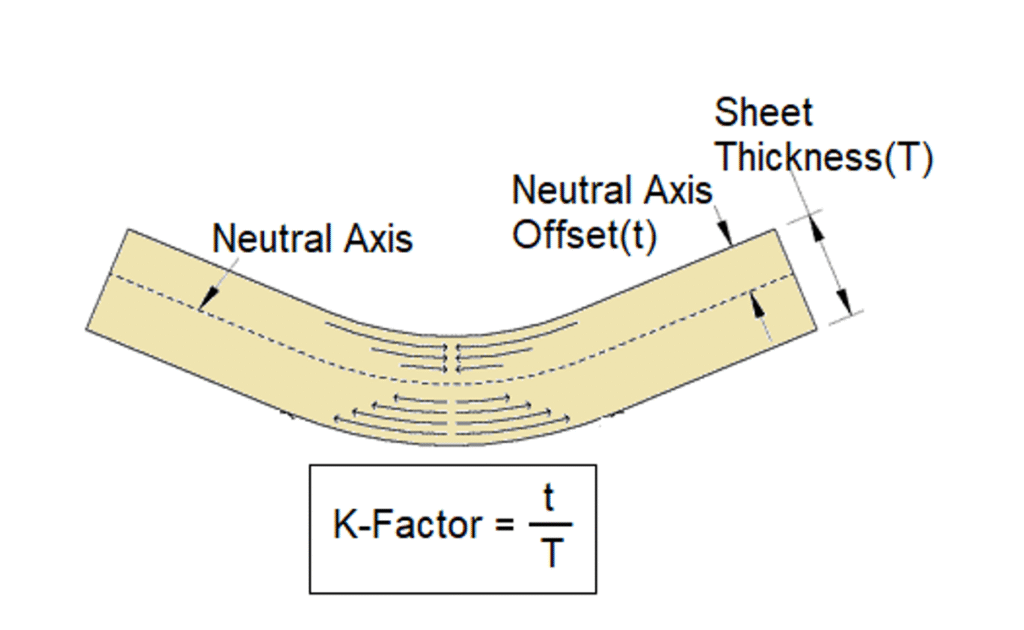

2. Sheet Metal Bending:

- K-factor represents the ratio of the distance from the neutral axis to the material thickness during bending.

- Used to calculate stretch and bend allowance in sheet metal work:

where = distance from inner face to neutral axis, and

= total material thickness.

3. Other Contexts:

- K-factor also appears in fields like engineering (fluid dynamics, fire protection), statistics, and the Elo rating system, each with a specific definition for its application.

If you specify a field (marketing, manufacturing, etc.), a more targeted explanation can be given.

The K-factor is crucial in sheet metal bending because it determines the position of the neutral axis, which is essential for accurately calculating the bend allowance and bend deduction—the measurements needed to develop a precise flat pattern before forming the bend. The neutral axis is where the material transitions from compression to tension during bending; understanding its shift helps fabricators predict how much the sheet will stretch or compress.

Key reasons for its importance include:

- Accuracy: Using the correct K-factor ensures that the developed flat pattern length will produce the desired final dimensions after bending, minimizing errors and rework.

- Material Efficiency: Proper K-factor calculations help reduce material waste and optimize the use of resources by consistently producing parts that meet specifications.

- Process Optimization: It allows manufacturers to standardize and streamline their bending processes, adapting for various materials, thicknesses, bend radii, and techniques.

- Quality Assurance: Accurate K-factor application ensures parts fit correctly in assemblies and meet tolerance requirements, which is vital for structural integrity and performance.

In summary, the K-factor is foundational for predicting material behavior during bending, enabling precise design and fabrication in sheet metal manufacturing.