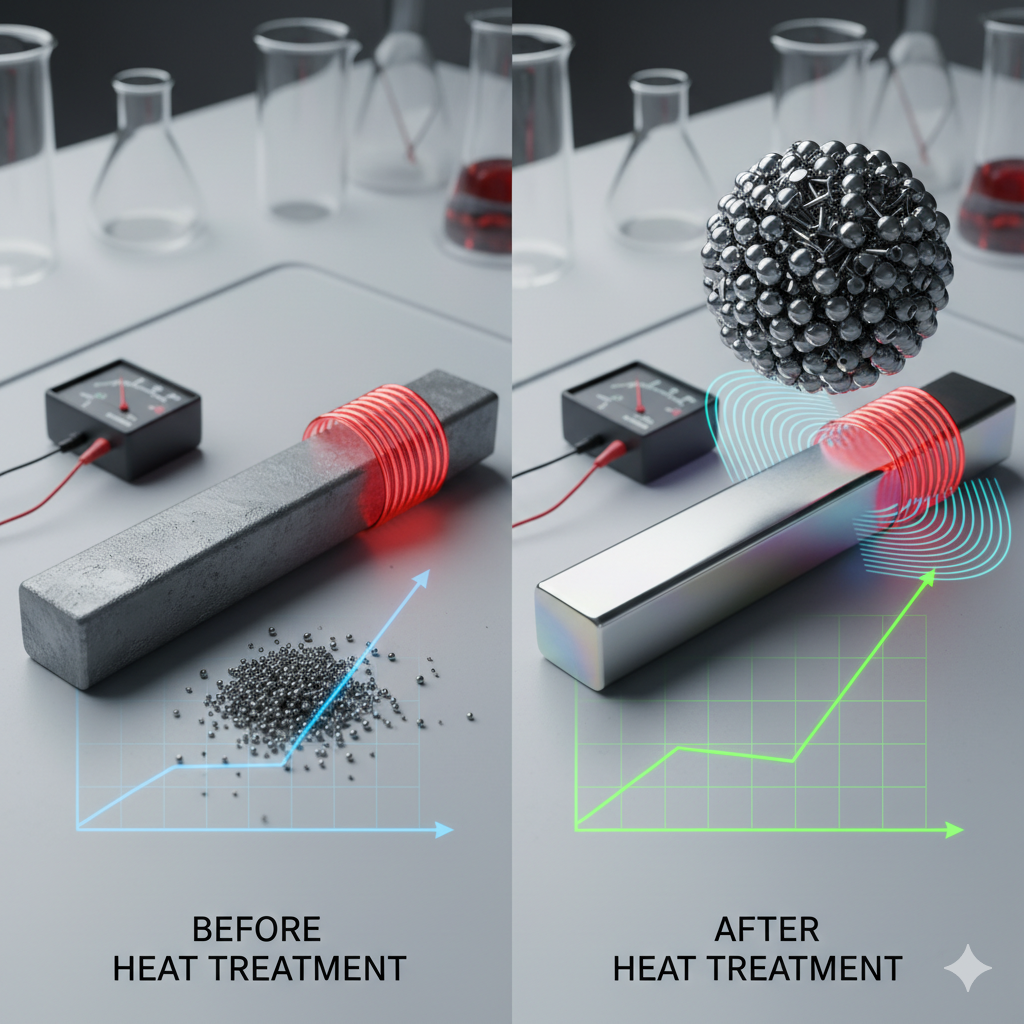

Heat treatment alters the electrical and magnetic properties of metals, such as steel, by changing their microstructure through controlled heating and cooling cycles.

Changes in Electrical Properties

- Electrical Resistivity: Heating steel increases its electrical resistance because heating causes more atomic vibrations, which scatter electrons, hindering current flow. After certain heat treatments and cooling, properties like resistivity may change permanently, depending on the final structure and phases present in the metal.

- Conductivity: Some heat treatments can improve or reduce electrical conductivity, tailoring the material for specific electronic or electrical applications.

Changes in Magnetic Properties

- Magnetic Permeability and Coercivity: Heat treatment such as annealing can increase magnetic permeability (making a metal easier to magnetize) and reduce coercivity (making it easier to demagnetize). This is useful for electrical steels in transformers or motor cores, which rely on efficient magnetic performance.

- Loss of Magnetism (Curie Point): Heating ferromagnetic metals like iron, nickel, and cobalt above their Curie temperatures causes them to lose their magnetic properties entirely. For example, annealed ferritic stainless steel becomes more magnetic, while certain heat treatments can also reduce or eliminate magnetism, depending on the process parameters (temperature, atmosphere, cooling rate).

Summary

By carefully selecting the heat treatment method and controlling time and temperature, engineers can enhance or reduce a metal’s electrical conductivity and magnetic permeability to meet the needs of applications in electronics, power generation, and magnetic devices.