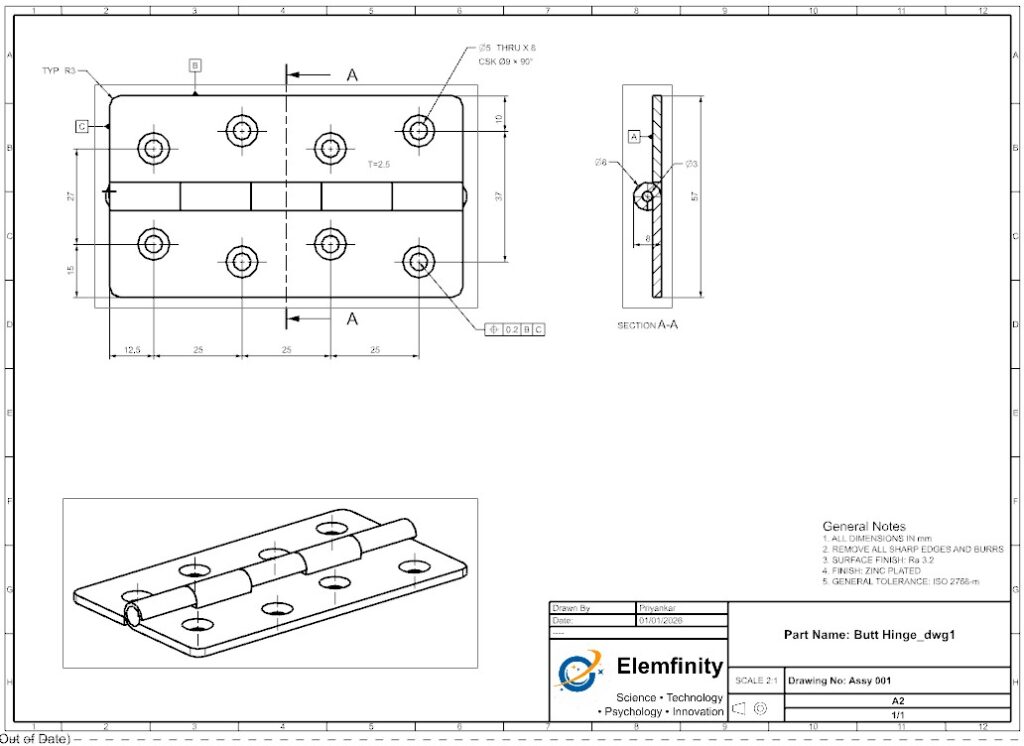

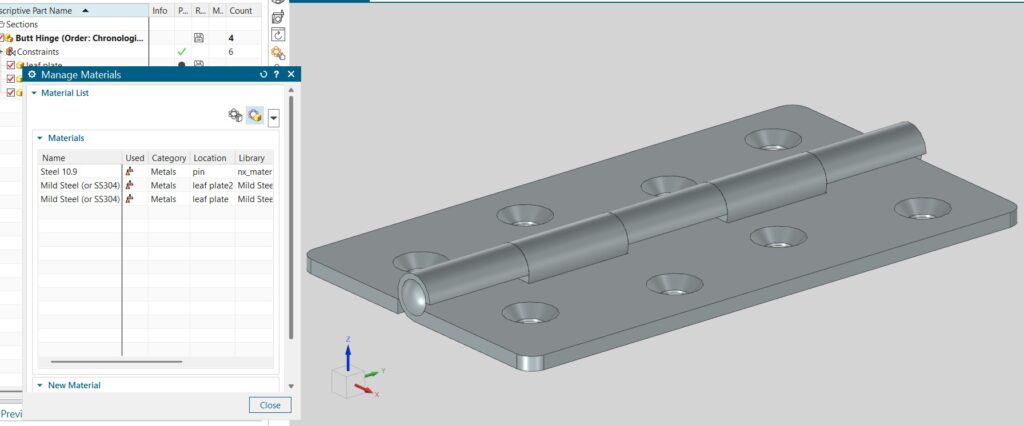

The attached image shows a 3D CAD model of a heavy-duty butt hinge, featuring two rectangular leaves connected by a central barrel pin, with multiple holes for fastening (likely using bolts like hex or Allen bolts discussed previously). This type of hinge is commonly used for truck and trailer doors, ramps, or panels where robust swinging motion and load-bearing capability are required.

Common Materials

Heavy-duty hinges like this are primarily made from mild steel (MS) or carbon steel for cost-effective strength in structural applications such as truck chassis or trailer gates. Stainless steel (grades 304 or 316) is preferred for corrosion resistance in exposed or refrigerated truck/trailer environments, while galvanized steel provides rust protection with added durability.dir.

Fasteners and Installation

The hinge’s bolt holes suggest use with high-tensile bolts (e.g., Allen or hex bolts in alloy steel), secured via welding or bolting to sheet metal or frames. Grease fittings or coatings enhance longevity under vibration and weather exposure.catalog.

This design aligns with standards for truck/trailer hardware, emphasizing strength, pivot smoothness, and easy maintenance.