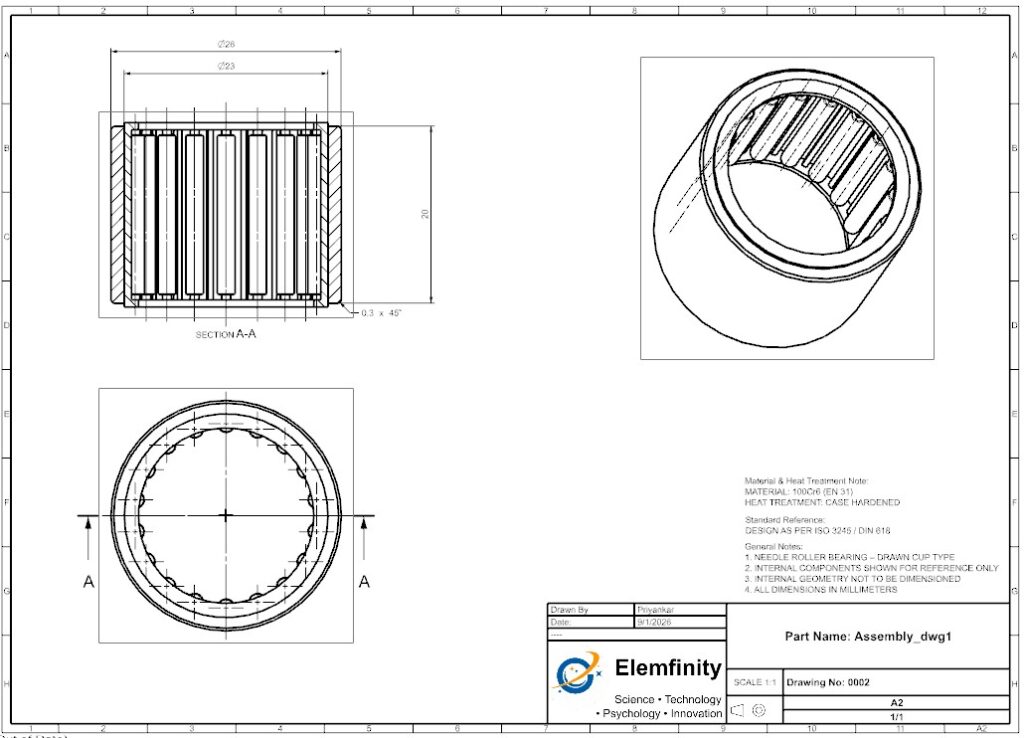

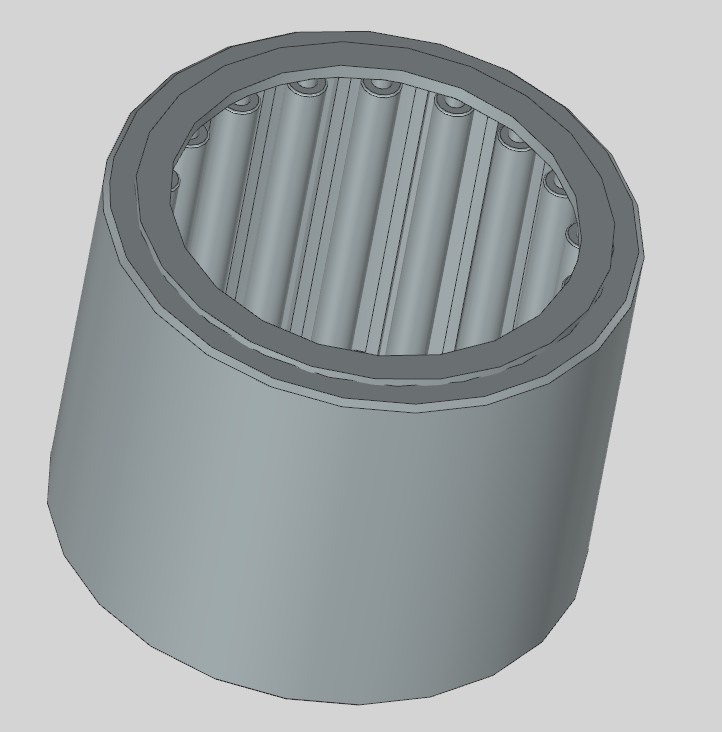

Cup needle roller bearing assembly (likely a full complement type without a cage), featuring thin cylindrical rollers arranged radially within an outer thin-walled shell, with inner ring details and precise dimensions labeled (e.g., outer diameter around 170mm). This design supports high radial loads in compact spaces, making it suitable for truck and trailer applications like transmissions, universal joints, steering linkages, rockers, and suspension pivots.

Key Features

Needle roller bearings excel in high load capacity relative to their small radial cross-section, low friction, and high-speed performance. The drawn cup outer race allows for easy press-fit installation, while the rollers provide precise guidance and reduced wear. They handle primarily radial loads but can accommodate some axial loads in certain configurations.

Materials Used

Rollers are typically made from high-carbon chrome steel (e.g., AISI 52100 or GCr15) for hardness and fatigue resistance. Outer cups use case-hardened low-carbon steel or carburized steel, with optional surface treatments for corrosion protection. Specialized variants incorporate stainless steel or vacuum-degassed bearing steel for harsh environments.

Applications in Trucks and Trailers

- Transmissions and gearboxes: Handle torque in constant mesh systems.

- Steering and suspension: Support pivots and linkages under dynamic loads.

- Truck/bus components: Used in wheel hubs, rockers, and Volvo/Renault truck models for durability.bajajbearings

- Trailers: In landing gear, ramp mechanisms, and axle assemblies.

- These bearings enhance vehicle reliability by minimizing friction and space usage in demanding, vibration-heavy operations.