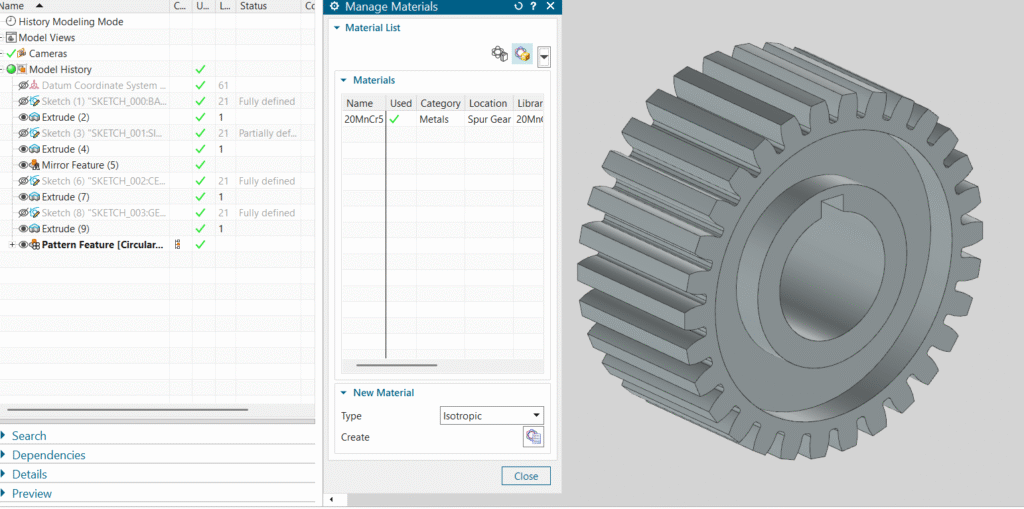

This is a solid spur gear with a keyed hub, used to transmit torque between two parallel shafts with a positive, non-slip connection

Visible features

- The gear has straight teeth cut parallel to the shaft axis, which identifies it as a spur gear designed for parallel-shaft drives.rs-online+1

- A thicker central hub is provided with an internal bore and keyway; the keyway mates with a key in the shaft so the gear and shaft rotate together without relative slip.

- The side faces are flat, with full-depth teeth across the face width, giving good load-carrying capacity and easy manufacturability on standard gear hobbing or shaping machines.

Function in a mechanism

- When meshed with another spur gear, each tooth pair transmits force along the line of action, converting input shaft rotation into output shaft rotation with a fixed gear ratio.

- Spur gears like this are typically used where high efficiency, precise speed ratio, and simple mounting on keyed shafts are required, such as gearboxes, machinery drives, and automation equipment.

Design advantages

- Straight-tooth spur gears are easy to design and manufacture, making them cost-effective while still offering high power transmission efficiency and predictable performance.

- The keyed hub allows straightforward assembly and disassembly, and the solid web/hub provides strength around the bore so the gear can handle significant torque without cracking or fretting at the shaft interface.