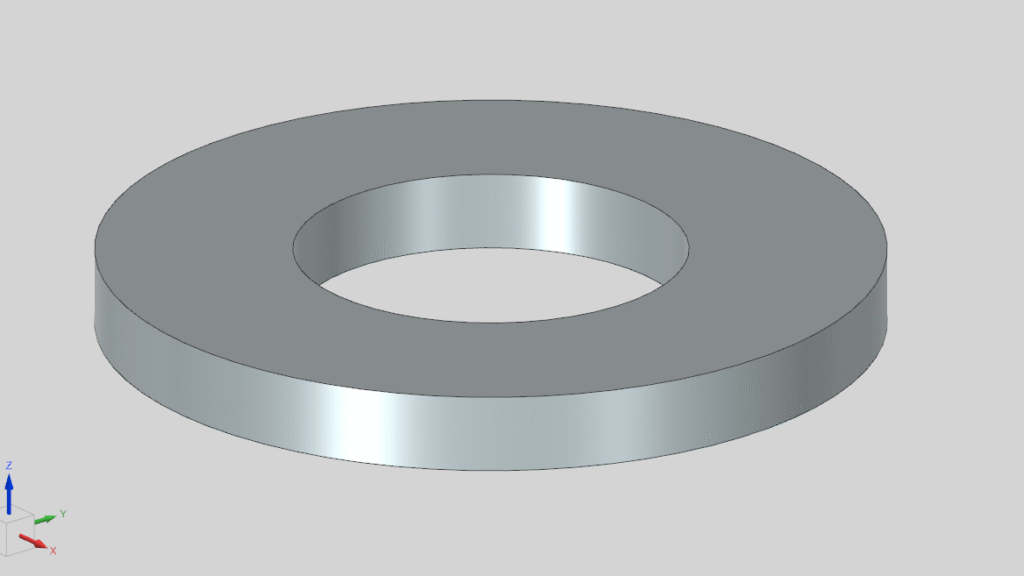

The image shows a 3D model of a flat washer, a common mechanical component widely used in fastening and assembly applications.

Description and Design

- The washer is an annular (ring-shaped) disc with a central hole, flat surfaces on both sides, and a consistent thickness throughout.

- The outer diameter is significantly larger than the inner diameter, which is designed to accommodate a bolt, screw, or threaded rod passing through the center.

Function and Applications

- Flat washers are primarily used to distribute the load of a threaded fastener (such as a bolt or nut), helping to prevent localized deformation or damage to the surfaces being clamped.

- They reduce the risk of “pull-through” by spreading force over a wider area, especially on softer materials like aluminum, brass, plastic, or wood.

- Washers also help prevent loosening due to vibration, protect the assembly surface from scratching, and in some cases are used to adjust the height or alignment of components.

Material and Standards

- Commonly manufactured from steel, stainless steel, brass, copper, nylon, or other engineering plastics, depending on corrosion resistance, load requirements, or electrical insulation needs.

- Standard dimensions are typically defined under ISO (e.g., ISO 7089, ISO 7090), DIN, or ANSI standards, which specify inner/outer diameter and thickness for each fastener size.

Usage Example

- In a bolted joint, the washer is positioned between the bolt head (or nut) and the adjoining surface, ensuring proper load distribution and reducing the risk of surface damage.

This flat washer is a simple yet essential component for achieving reliable, durable, and safe mechanical connections in a wide range of engineering and construction applications

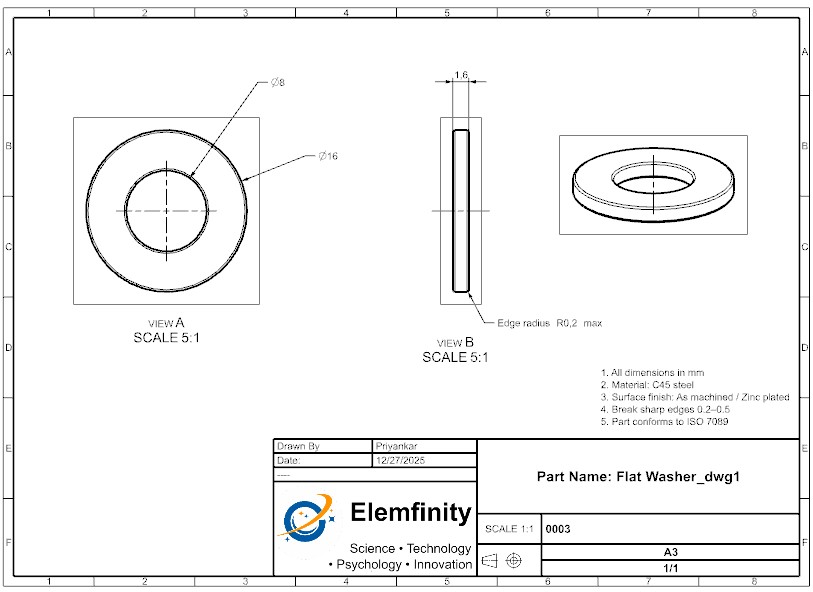

Drawing: